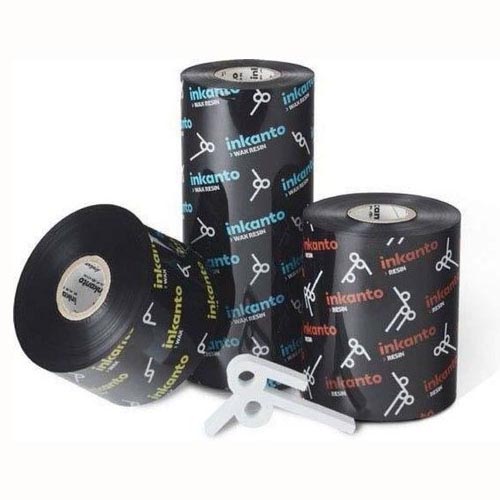

Thermal Transfer Ribbon is just a polyester sheet with several layers applied on it. The heat produced by the thermal printer's thermal head transfers the ink layer to the label.

© 2021 Markaa Barcode Solutions Designed & Maintained By ITology